Choose Bio Acetate For Eyewear

A Presentation by

BioAcetate S70

A Material for Sustainable Development

BioAcetate.com

Agenda

1Introducing BioAcetate S70

2Eco-Benefits

3Performance Benfits

4Injection & Handmade Frames

5Limitations & Summary

Introducing BioAcetate S70

Environmentally friendly and

Sustainable

High Performing

Alternative CA Material

Suitable for Injection and Handmade Frames

Video Introduction

Amidst the context of climate change, pollution, and waste

By striving to mitigate climate change and promote Sustainable Development and a Circular Economy, BioAcetate S70 plays an active role in fostering a more environmentally responsible future.

02 Eco-Benefits

BioAcetate S70’s 5 Main Eco-Benefits

5-Main Eco-Benefits

1. ISCC Sustainability Carbon Certification

2. 62% biobased according to ASTM-D6866

3. Biodegradable according to ISO-14855

4. Harmful plasticizers free (NO DEP)

5. Biocompatibility according to ISO-10993

*All Test Reports & Certifications can be found and downloaded online on the website: https://bioacetate.com/certifications/

Eco-Benefit 1

“The International Sustainability & Carbon Certification (ISCC) is an international certification system covering all kinds of bio-based feedstocks and renewables catering to energy, food, feed, and chemicals sectors.”

By obtaining the ISCC certification, brands gain the privilege to incorporate BioAcetate S70 into their established ISCC-certified supply chains.

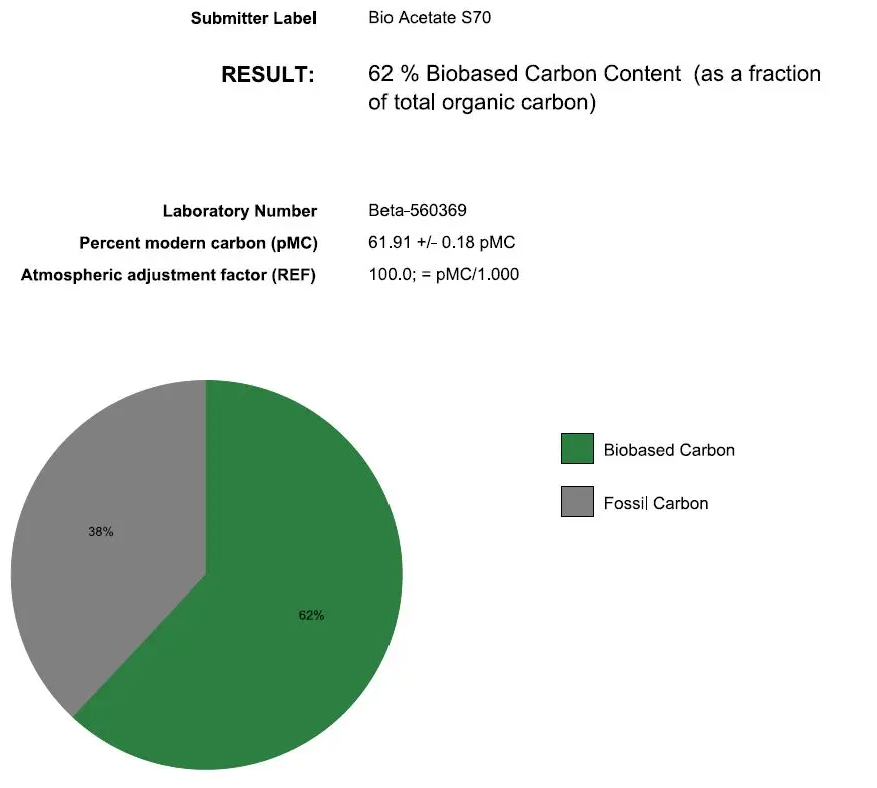

Eco-Benefit 2

62%

Biobased According to ASTM D-6866

Eco-Benefit 2

Utilizing biobased materials contributes to sustainable development:

➔ Facilitates the shift towards renewable resources

➔ Aids in lessening reliance on fossil fuels

➔ Minimize greenhouse gas emissions

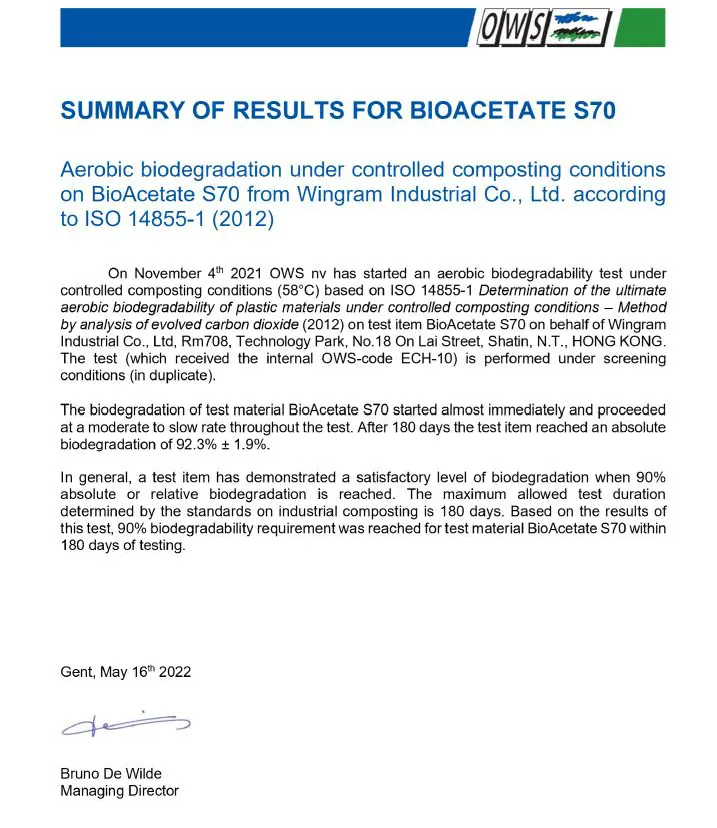

Eco-Benefit 3

>90%

Within 180 days

Biodegradable According to ISO-14855

Eco-Benefit 3

“In general, a test item has demonstrated a satisfactory level of biodegradation when 90% or relative biodegradation is reached.”

“90% biodegradability requirement was reached for test material BioAcetate S70 within 180 days of testing.”

Hence, BioAcetate S70 demonstrates ultimate biodegradability in compliance with ISO-14855.

(2022 Test Result)

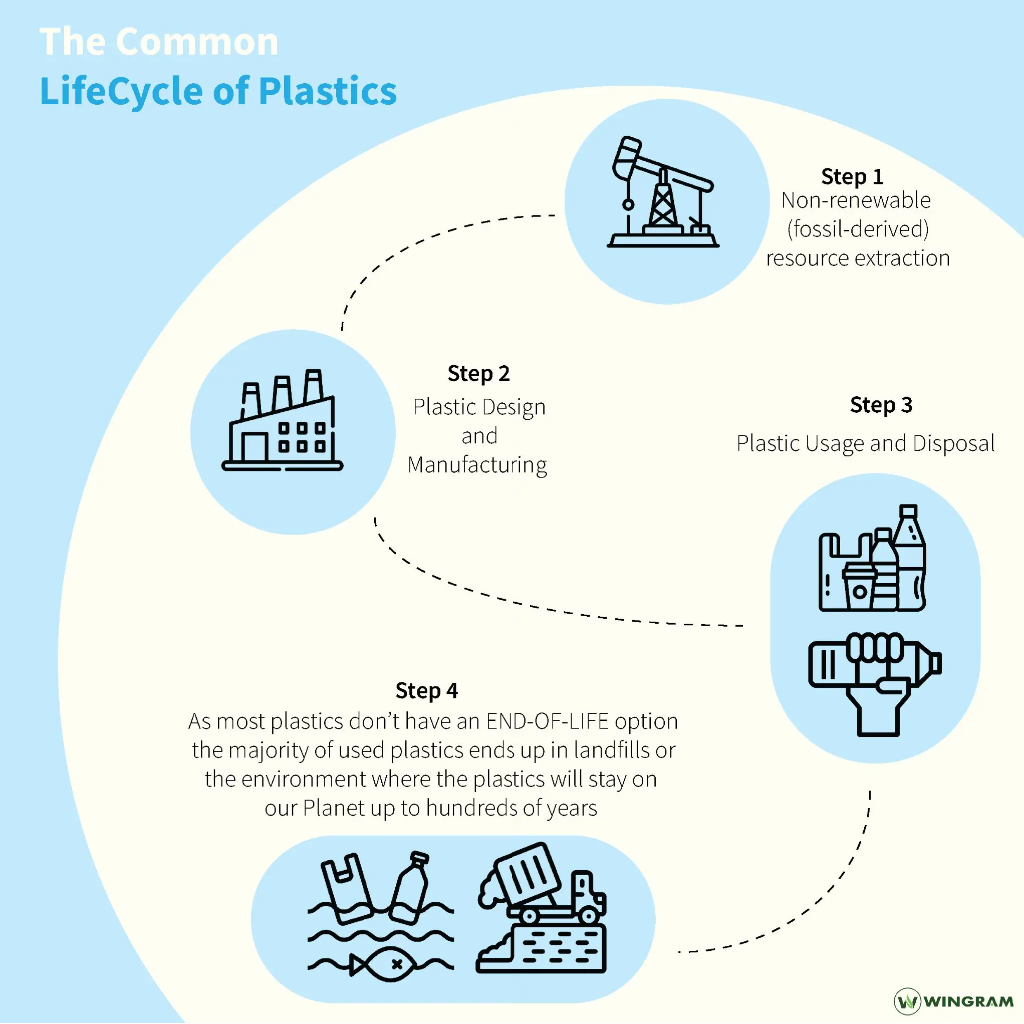

Most plastics are designed to be used and discarded without any consideration afterward!

Based on a 2021 report from the United Nations, approximately 79% of all plastics ever produced are ultimately disposed of in landfills or end up polluting the environment.

Biodegradability contributes to sustainable development by providing an end-of-life solution that allows materials to naturally return to the Earth after use.

Eco-Benefit 4

100%

DEP and harmful plasticizers Free

✖ DEP

✖ BPA

Eco-Benefit 4

Extensive testing confirms that BioAcetate S70 is devoid of any harsh or harmful chemicals to ensure its safety for human use.

➔ Reach EU Compliant

➔ NO DEP

➔ NO BPA

➔ ROHS EU Compliant

Eco-Benefit 5

Biocompatibility

This product has been verified as non-skin sensitizing and non-irritating through testing.

(ISO-10993)

BioAcetate S70 brings out

Smiles

because it is not only better for the

Earth

but it is also better for your

Health

These 5 Eco-Benefits make BioAcetate S70: A Circular Economy Product

Lifecycle Stages

01 Biobased Raw Materials

Minimize reliance on finite resources.

02 Design and Production

Research and development aim to enhance the performance and benefits of conventional cellulose acetate

03 Better Product

Design a product that promotes both environmental sustainability and human health by being free from DEP and biocompatible.

04 End-of-Life Option

After use, it undergoes biodegradation

05 JSCC Certified:

Help Offset Carbo Footprint

As a supplier, it is our duty to safeguard the Earth’s resources and climate for the benefit of future generations.

03 Performance-Benefits

Heating with HECA enhances the performance benefits of BioAcetate S70

Hardness Enhanced CA (HECA)

The unique formulation and production process of BioAcetate S70 result in an exceptionally robust material that maintains its strength without becoming brittle.

HECA Leads to:

1. Thinner Frames

2. Safeguarding from Distortion

3. Reduced Processing Expenses

4. Successfully withstand Perspiration Resistance test (48 hours)

Why HECA Matters?

➔ Similar to any sector, innovation and change are unavoidable.

➔ In this instance, innovation takes place during the initial stages of the supply chain, specifically at the raw material level.

➔ The development of HECA as a performance enhancer aimed to elevate the eyewear industry and enhance its products.

➔ As a supplier of raw materials, it enabled the flexibility to address issues at the fundamental stages of the product, rather than being dependent on the constraints of alternative materials.

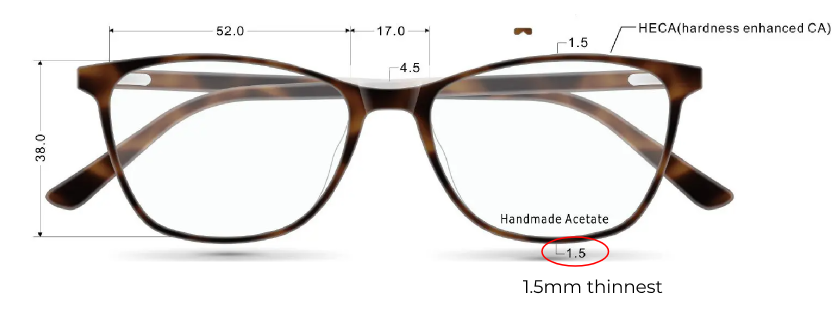

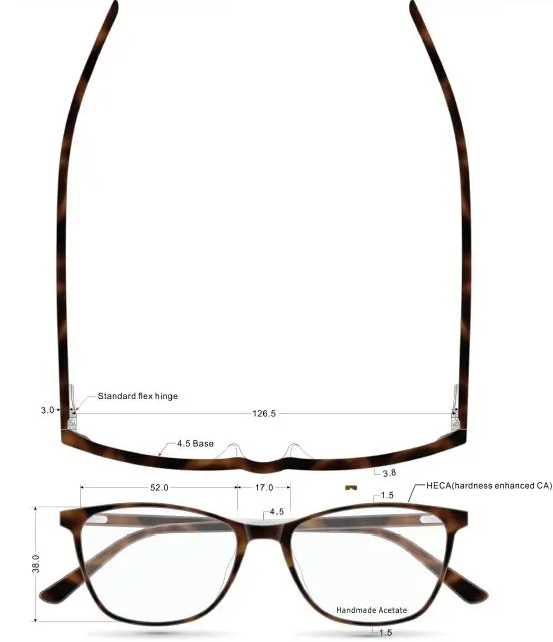

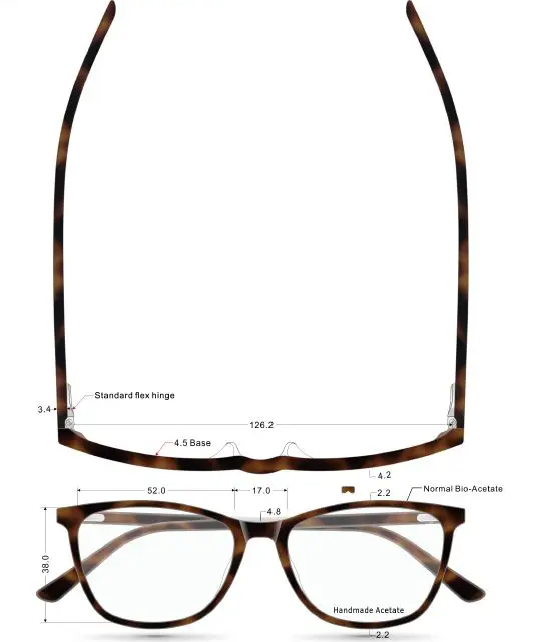

Performance-Benefit 1

Thinner Frames

Greater design flexibility is achievable as the increased hardness allows for the creation of thinner frames.

Design and Frame with BioAcetate S70

➔ Utilizing BioAcetate S70 (Figure 1), frames can be manufactured with a slimness of up to 1.5mm

➔ With conventional acetate (Figure 2), frames can be crafted to be as thin as 2.2mm

➔ Thanks to the exceptional hardness properties of BioAcetate S70, there is a notable difference of 0.7mm

Figure 1

Figure 2

More design flexibility with BioAcetate S70

Limitations with Conventional Acetate

Performance-Benefit 2

Protection Against Deformity

Due to its enhanced hardness, frames exhibit reduced susceptibility to shrinking and deforming compared to conventional acetate materials.

HECA Offers Protection against Deformity

Anomalies in traditional acetate could lead to the lens detaching from the frame

Anomalies in standard acetate may lead to significant disparities in height between the temple/legs

Performance-Benefit 3

Lower Processing Cost

HECA enables a more efficient surface treatment process, resulting in reduced costs.

Benefit: Surface treatment for BioAcetate S70 frames is more straightforward compared to other injection materials like Nylon or CP/CAP.

Reason: BioAcetate S70’s superior hardness, courtesy of HECA, streamlines the polishing process and eliminates the need for varnishing.

Therefore: Facilitates cost savings in labor and operations.

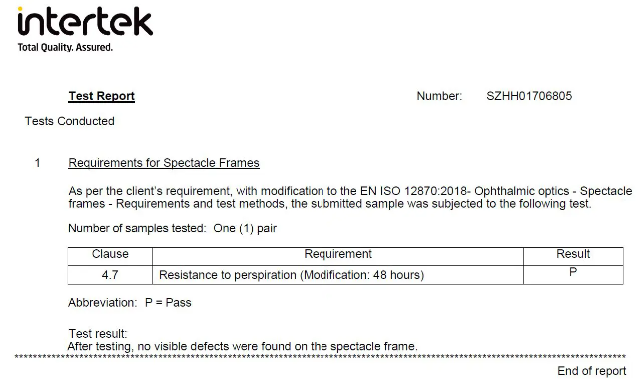

Performance-Benefit 4

Pass Resistance to Perspiration Test

Frames crafted from BioAcetate S70 successfully pass the Resistance to Perspiration Test (48 hours) in accordance with the requirements of BS EN ISO 12870:2018.

Pass Resistance to Perspiration:

Intertek conducted testing for the requirements and test methods of spectacle frames.

● Modification to 48 hours instead of 24 hours

● Testing done according to EN ISO 12870:2018

● No visible defects after 48 hours

In Conclusion

BioAcetate S70 is meticulously engineered as a superior material, meeting stringent international standards while delivering exceptional performance and noteworthy eco-friendly advantages.

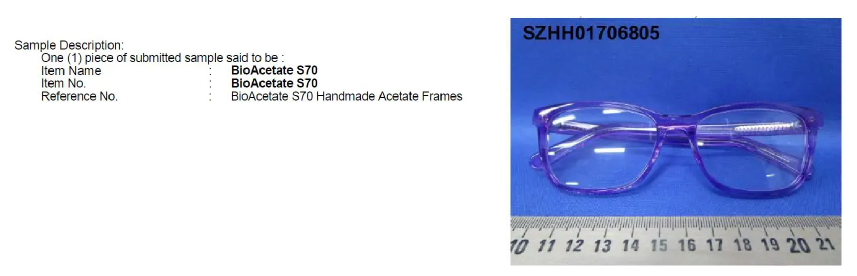

04 Suitable for Both Injection & Handmade Frames

BioAcetate S70 offers eco-friendly and performance advantages to both Injection Frames and Handmade Acetate Frames

(1) For Injection Frames:

BioAcetate S70 is available in pellets/granules form

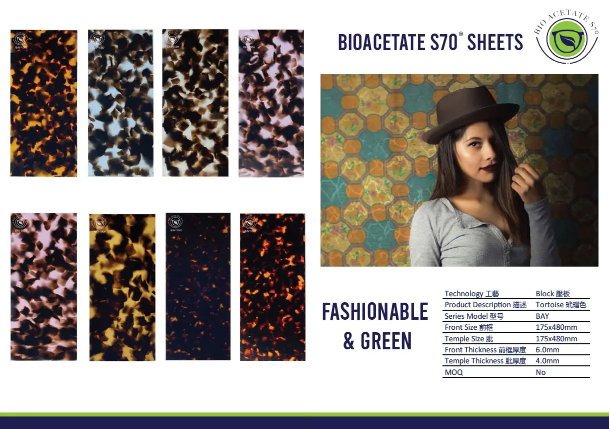

(2) For Handmade Acetate Frames:

BioAcetate S70 is available in BioAcetate S70 sheets/slabs

BioAcetate S70 Injection Special Trait

Due to the absence of varnishing requirements and its enhanced hardness, BioAcetate S70 injection frames can replicate the look and feel of handmade acetate frames.

BioAcetate S70 Handmade Acetate

Advantages Highlights

➔ Protection against deformity

➔ Frames are extra hard but not brittle

➔ Can easily insert temple core wire

➔ Compatible with AC/PC Lens

➔ HECA hardness benefits

➔ BioAcetate S70 Eco-benefits

BioAcetate S70 Handmade Acetate Trait Highlight

Thanks to HECA’s inherent hardness, BioAcetate S70 acetate frames crafted by hand offer enhanced protection against shrinkage and deformation.

06 Summary

Summary of BioAcetate S70 strengths and a mention of its limitations

Innovation from Raw Materials Perspective

The primary aim of BioAcetate S70 is to revolutionize the eyewear industry by diligently addressing core issues and implementing enhancements in both injection and handmade acetate frames.

Crafting a material that not only benefits the Earth but also enhances performance.

5 Main Eco-Benefits

1. ISCC Sustainability Carbon Certification

2. 62% Biobased According to ASTM D-6866

3. Biodegradable According to ISO-14855

4. Harmful Plasticizers Free (NO DEP)

5. Biocompatibility According to ISO-10993

4 HECA Performance Benefits

1. Thinner Frames

2. Protection Against Deformity

3. Lower Processing Cost

4. Pass Resistance to Perspiration test (48 hours)

Early Stage Limitations

→ Currently, the primary focus and advantages of BioAcetate S70 lie not in its designs but in its eco-friendliness and exceptional performance benefits.

→ As BioAcetate S70 is a novel material, the selection of colors and designs for handmade acetate slabs/sheets is currently limited. Nevertheless, custom-made designs are a viable option, and over time, an expanding array of colors and designs will naturally become accessible.

→ Given that BioAcetate S70 is available in pellets/granules specifically designed for injection frames, the primary constraint often lies with manufacturers who may lack experience in working with this innovative material. Therefore, seeking assistance from Wingram’s technical support becomes crucial to address this matter effectively.

Despite its early stage limitations, BioAcetate S70 is a one-of-a-kind material that is

➔ ISCC Sustainability Certified

➔ Biodegradable (ISO-14855)

➔ Extra-hard (HECA)

➔ Has Protection Against Deformity

BioAcetate S70:

Better Earth & Better Performance!

Achieving Our Sustainability Goals!

Frequently Asked Questions

What advantage BIO-BASED acetate does have?

The bio acetate is made from eco-friendly as well as all-natural sources, for that reason, it assists to decrease the reliance on restricted fossil resources and also the CO2 exhausts.

Bio-based acetate likewise provides various other benefits such as being Environmentally friendly.

Bio-Acetate is created to have comparable characteristics/properties and also features to traditional Cellulose Acetate (CA).

The BioAcetate S70 is a lasting and also green substitute to standard CA. Versus the background of the globally ecological dilemma, our team believes that it is necessary as a resources plastics manufacturer to do something about it to offer options to our ecological issues.

Particularly, our BioAcetate S70 looks to address the concerns of conventional CA by being a product that is much better in both (1) functional performance-wise as well as (2) its ecological effects.

Do you have any suggestions for BioAcetate's Hardness Enhanced CA (HECA)?

Among the primary benefits of BioAcetate is that the HECA, which implies that BioAcetate S70 is a lot less breakable than standard acetate. As one can picture, this has numerous useful applications. To highlight, a more powerful as well as extra long-lasting product that does not give up efficiency enables thinner eyeglasses frames creates to be made. Thinner frames can currently be made with BioAcetate S70’s HECA.

Is BioAcetate S70 ideal material for injection production?

Yes, our BioAcetate S70 is meant both for shot molding as well as acetate sheet manufacturings.

BioAcetate S70 has 3 different qualities, among which is enhanced for shot molding.

One point to maintain note is that the equipment utilized for BioAcetate S70 have to be cleansed to stay clear of Computer plastics contamination.

Please call our sales group for even more technological details.

What do your certifications as well as worldwide standards?

Since many individuals do not have the know-how, atmosphere, and also time for it, it is nearly difficult to confirm if an item is biobased or naturally degradable. That is why our team believes it is very important that customers inform themselves of the existing requirements as well as qualifications that regulate these locations. Every one of Wingram’s items is licensed from trusted third-party establishments. When it comes to our Bio Acetate S70, organizations such as Fraunhofer from Germany, and also Beta Analytic from the United States, along with SGS from Switzerland have actually validated our ecological cases.

Our team believes that worldwide screening requirements exist to link the crooked informative void in between consumers and also manufacturers. All our screening and also outcomes are openly shown under our “Certifications” web page..

The item has actually been examined with the most strict worldwide criteria of EN13432, ISO14855, and also ASTM D6400. We are additionally accredited by credible third-party organizations: Fraunhofer from Germany, as well as Beta Analytic from the USA.

Could you please suggest 5 BIO Acetate Manufacturers & Suppliers?

Yes. Polarized lenses help to reduce glare from water, hood of the car, pavements, and road.

Top 1 Bio acetate manufacturers:

Biodegradability M49

When you consider plastic, in this duration, you right away think about something unfavorable, both for the beginning products as well as for the trouble of disposal. What if we informed you that M49 is not plastic typically comprehended? In fact, M49 is made up of cellulose acetate as well as a plasticizer of veggie beginning. The resulting formula is mainly made up of products from sustainable resources.

Cellulose is an all-natural polymer that stands for the foundation of the entire plant kingdom.

Get acetic anhydride Cellulose Acetate by responding cellulose. Plasticizers are after that contributed to Cellulose Acetate to enhance its physical qualities as well as workability, to turn into one of the most crucial basic materials for the manufacturing of glasses.

Mazzucchelli 1849 has actually expected the advancement of the marketplace by establishing in its research laboratories a formula that integrates the physical-mechanical features of the classic formula with a quality of solid eco-sustainability: M49.

Standard plasticizer has actually been changed by a plasticizing service of the veggie beginning, therefore bioplastic with impressive bio-based web content.

Website: https://www.mazzucchelli1849.it/pages/m49-bioplastic?locale=en

Top 2 Bio acetate manufacturers:

Shenzhen Jimei New Material Co., Ltd

Jimei New Material Co. Ltd is based in Shenzhen as well as was created in 2006. Jimei is a cellulose acetate manufacturer that concentrates on the layout, manufacturing, and also circulation of acetate sheets.

Jimei acetate sheets can be made use of to produce acetate spectacles frames, along with acetate sunglasses.

Jimei gives top-notch items by making use of brand-new modern technology, the very best basic materials readily available on the marketplace, and also the experience of its personnel.

As an acetate manufacturer, Jimei has actually developed right into a favored provider for internationally identified brand names.

Jimei uses sophisticated modern technologies to create their acetate sheets, consisting of extrusion modern technology, block modern technology, in addition to lamination modern technology. Jimei extrusion innovation is defined by vivid shades, excellent appearance, and also simple handling.

Jimei block craft acetate sheets include pre-shaped and also pre-colored granules. Block craft includes various results, consisting of turtle, place, geometric form, marble and also camouflage, to name a few. Jimei laminated acetate sheets include pet prints as well as watercolors.

Site :https://www.jimei123.com.

Top 3 Bio acetate manufacturers:

Jinyu Plastic Products Limited

Jinyu is a cellulose acetate manufacturer founded in 2003. Jinyu eyewear=acetate sheets are utilized to make optical frames, to name a few items.

The objective of Jinyu is to generate top-quality cellulose acetate products according to distinct consumer requirements.

Jinyu takes satisfaction in its capacity to constantly establish brand-new products with eye-catching styles. Jinyu optical frames likewise are available in a range of tones as well as ingenious frameworks, consisting of overlay mix shade, layer mix shade, along dual mix colors,

To put it simply, Jinyu bio acetate or acetate frames, as well as sunglasses, are readily available in a range of shades, consisting of yellow, red, purple, environment-friendly, blue, black, along brownish.

Additionally, the classifications for Jinyu acetate glasses consist of extrusion, completely dry block, damp block, in addition to lamination.

Jinyu is open to obtaining unique demands as well as patterns from consumers for brand-new item growth.

Jinyu acetate sheets satisfy global requirements.

Website: http://jinyuplastic.com/

Top 4 Bio acetate manufacturers:

BioAcetate S70

BioAcetate S70 is a popular Wingram Industrial Company Limited. In regards to area, Wingram’s head workplace lies in Hong Kong with manufacturing facilities in Malaysia and also China. Wigram’s company concentrates on supplying remedies to resolve the progressively widespread ecological problems of our planet. The company is concentrated on developments on lasting plastics and also looks to accomplish this by creating eco-friendly plastics.

Various other locations of Wingram’s concentrates remain in, as an example, the manufacturing Polylactic Acid (PLA) items, such as PLA coffee covers ( https://eco-greatriver.com/), or the r & d of naturally degradable ingredients for plastics. Wingram has a recycling factory in Malaysia that aids alleviate the issues of plastic use.

https://bioacetate.com/about/

Top 5 Bio acetate manufacturers:

BIOTATE

Bio-Cellulose Acetate.

Is among the finest quality and also finest superior products for the building and construction of glasses,

primarily made from cotton as well as timber pulp.

It is extremely long-lasting, immune to temperature level adjustments, therefore comfy, and also versatile to use for a prolonged time period. Cellulose acetate has broader selection of dynamic and also brilliant color selections.

then various other plastic products, along with a much heavier.

as well as higher visual sensation

.

All biotate manufacturing is made inside our very own manufacturing facility, from granules to end up acetate sheets.

https://www.biotate.green/

Contents

- Introducing BioAcetate S70

- Video Introduction

- 02 Eco-Benefits

- 62%

- >90%

- 100%

- 03 Performance-Benefits

- Hardness Enhanced CA (HECA)

- Why HECA Matters?

- Thinner Frames

- Design and Frame with BioAcetate S70

- Protection Against Deformity

- HECA Offers Protection against Deformity

- Lower Processing Cost

- Pass Resistance to Perspiration Test

- Pass Resistance to Perspiration:

- 04 Suitable for Both Injection & Handmade Frames

- (1) For Injection Frames:

- (2) For Handmade Acetate Frames:

- BioAcetate S70 Injection Special Trait

- BioAcetate S70 Handmade Acetate

- Advantages Highlights

- BioAcetate S70 Handmade Acetate Trait Highlight

- 06 Summary

- Innovation from Raw Materials Perspective

- 5 Main Eco-Benefits

- 4 HECA Performance Benefits

- Early Stage Limitations

- BioAcetate S70:

- Frequently Asked Questions

- Want to Find A Eyewear Supplier from China?